ARS provides on-line inspection systems based on X-Ray technology. Inclusions, internal and external defects, weighing and differential weighing analysis, density analysis, integrity and completeness checks, form and shape controls, packaged products inspections and bulk products counting can be revelead through ARS X-Ray inspection systems, even where high speed production rate is required.

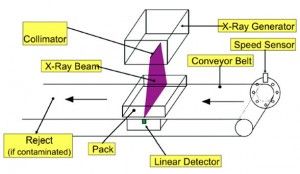

Working Principle

X-Ray technology allows to analyze product density. Density variations can be connected with material defects such as inclusions, bubbles, porosity. Different material are subjected to different radiation absortion: X ray inspection systems measure this difference impriming a digital radiological image through a greyscale. Different materials are revealed with different grey tons.

The amount of radiation absorbed by the product during the inspection depends on its thickness and density and on its atomic mass number.

During an X-Ray inspection, product transits few milliseconds through an X-Ray beam: depending on the material properties it will absorpe a little quantity of radiation, whereas the rest will reach the detector, impriming a radiological image. As different materials have different properties, a different amount of radiation will reach the detector. The result is an image with different tons of grey.

Thanks to processing software it’s possible to highlight defects and inclusions but also a large amount of information that allows statistic analysis on production quality

ARS X-Ray quality control systems are designed to meet the to customer’s requirements; they are also HACCCP (Hazard Analysis and Critical Control Points) compliant.

X-Ray technology allows contaminants detection and products inspection both on unpackaged and packaged products. Packages can be made of glass, metal, ceramic, plastic, cardboard.

Variations in temperature and humidity of both product and contaminant don’t affect detection accuracy and reliability.

Unlike traditional inspection systems, X-ray quality control is able to analize even aluminum or metallized film.

X-ray inspection systems are the best solution to ensure product integrity and avoid customer complaints.

Applications:

Inclusions Detection

If compared with traditional inspection systems such as metal detector, not only do X-ray detectors reveal metallic inclusions but also non-metallic intrusions, both on unpacked and packed products, even with aluminum or metallized film.

Regardless of shape, size or position, the following inclusions can be detected: cement, ceramics, rubber, metal, minerals, bones, glass, plastic.

What packages can be examined? Our inspection systems can perform analysis on both rigid packaging, including glass, metal, ceramic, plastic and cardboard containers but also on bags and tubes.

Weighing and Differential Weighing

ARS quality control instruments can distinguish different density elements inside a sealed package, calculating every elements weight. Thanks to density analysis it’s possible to distinguish the presence of different components within a pack and their weight.

ARS X-ray machines also offer the innovative feature of differential weighing that allows to analyze the fat content in meat muscle, always guaranteeing non invasive and HACCP compliant inspections.

Integrity and Completeness Check

X-ray instruments allows simultaneous controls, replacing traditional inspection systems such as weighers and metal detectors.

✓ Count:

Through a grayscale image, products with different densities can be highlighted. ARS inspection systems reveal, count and weigh different elements inside sealed package, regardless of their position, shape and size within the packed product.

✓ Seal inspection:

X-ray technology allows integrity verification on sealed packs. ARS inspection systems provide detailed information on seal integrity in order to guarantee product compliance.

✓ Fill Level Inspection:

ARS x-ray systems allows fill controls on packaged products. No matter if liquid or solid, X-ray technology permits to verify and to set maximum and minum fill levels. ARS quality control system can work even with high speed inspection rate.

✓ Shape Verification:

X-Ray inspection systems control products size, shape and position inside their own packaging. dimensional deviations can be detected even with aluminum or metallized film.

✓ Presence/Absence Check:

Radiological analysis check package completeness: all components presence can be verified and counted inside a sealed pack.