Sorting operations can be efficiently performed by Flexibowl®. FlexiBowl® can handle different parts simultaneously: parts are recognized by the vision system.

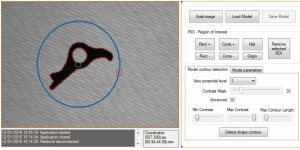

Thanks to FlexiVision, the integrated vision system that can be optionally supplied with FlexiBowl®, parts are distinguished and separated.

Parts sorting is recommended only if parts do not require a precise order in the feeding process: parts can be available in different quantities in the vision area.

Parts sorting: how does it works?

Once parts pattern has been identified throught FlexiVision, the system can recognize the different components on the Flexibowl® feeder.

Parts on the vision area are recognized and picked up by the robot.

Parts availability on the vision area follows a stochastic trend: it is not possible to sort parts in a specific order.